Introduction

Force sensors are critical components in many industrial and research applications, allowing for precise measurement of forces and torques in different directions. However, traditional force sensors were limited to measuring forces along a single axis, which could lead to inaccuracies and limitations in certain applications.

With the advancement of technology, 6-axis force sensors have been developed to overcome these limitations and provide more precise and comprehensive force measurements. In this guide, we will delve into the world of 6-axis force sensors, exploring their capabilities, applications, and how to effectively use them for mastering precision.

What are 6-Axis Force Sensors?

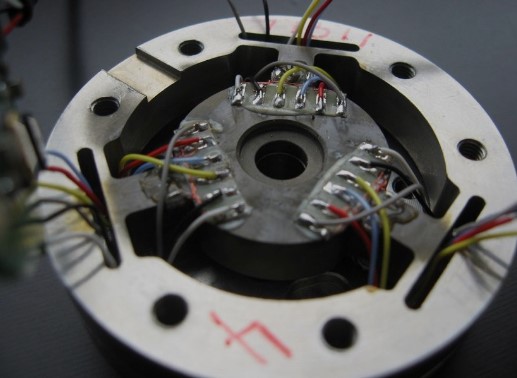

As the name suggests, 6-axis force sensors can measure forces and torques in six different directions – three linear axes (X, Y, Z) and three rotational axes (roll, pitch, yaw). This allows for a more comprehensive understanding of force interactions in complex systems.

How Do 6-Axis Force Sensors Work?

6-axis force sensors typically consist of multiple strain gauges arranged in a Wheatstone bridge configuration. When an external force is applied to the sensor, it causes deformation and changes in the resistance of the strain gauges. This change in resistance is measured and converted into force and torque values.

Key Features of 6-Axis Force Sensors

- Six degrees of freedom (DOF): As mentioned, 6-axis force sensors can measure forces and torques in six different directions, providing a more complete picture of force interactions.

- High precision: With advanced strain gauge technology and signal processing algorithms, 6-axis force sensors can provide highly accurate measurements.

- Compact size: Unlike traditional multi-axis force sensors that require multiple components to measure forces in different directions, 6-axis force sensors are compact and can be integrated into smaller systems.

- Real-time data acquisition: Many 6-axis force sensors come with software or interfaces that allow for real-time data acquisition and analysis, providing instant feedback on force interactions.

- Customizable options: 6-axis force sensors can be customized to fit specific application needs, such as size, range, and frequency response.

Applications of 6-Axis Force Sensors

6-axis force sensors have a wide range of applications in various industries. Some common areas where they are used include:

- Robotics: In robotic systems, 6-axis force sensors can be used to monitor forces and torques applied by the robot arm, providing feedback for precise motion control.

- Aerospace and automotive: In these industries, 6-axis force sensors are used for testing and monitoring structural components’ performance under loads.

- Medical research: 6-axis force sensors are used to measure forces and torques in biological systems, providing insights into the biomechanics of movements.

- Material testing: 6-axis force sensors can be used in material testing to accurately measure forces and torques applied to samples during experiments.

Tips for Mastering Precision with 6-Axis Force Sensors

- Proper calibration: It is crucial to calibrate your 6-axis force sensors regularly to maintain accuracy and reliability.

- Understanding the measurement range: Each 6-axis force sensor has a specific measurement range, and it is important to choose the right sensor for your application needs.

- Consider environmental factors: External factors such as temperature and humidity can affect the performance of 6-axis force sensors, so it is important to consider these factors during data acquisition.

- Understand the coordinate system: 6-axis force sensors measure forces and torques in a specific coordinate system, so it is essential to understand how this system relates to your application.

Conclusion

In today’s world where precision and accuracy are crucial, 6-axis force sensors provide a valuable tool for measuring forces and torques in multiple directions. From their working principles to applications and tips for mastering precision, this guide has covered the key aspects of 6-axis force sensors. By understanding these concepts and applying them effectively, you can harness the full potential of 6-axis force sensors in your projects.